Sapphire nozzle 131

- MVT AG - micro technologies

- Products

- Surface treatment

- Sapphire screw-in nozzles

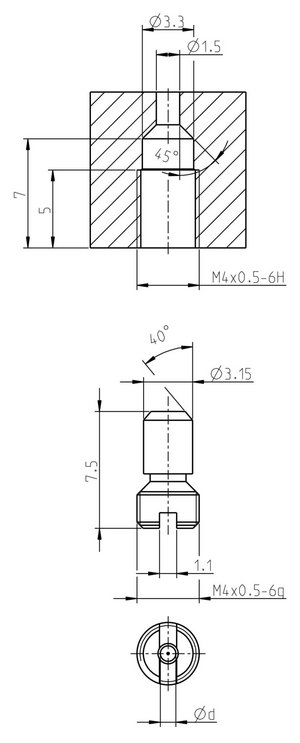

- Sapphire nozzle 131

The high-performance Sapphire nozzle type 131 is designed for surface treatment. The nozzle is characterized above all by its long service life, efficiency and quality. This nozzle was designed for customer-specific applications up to an operating pressure of 3000 bar.

The heart of the nozzle, its the sapphire that is completely manufactured by mvt AG, thus ensuring a consistent and high quality. All sapphire are checked for scratches, cracks and flow.

This product is compatible with the following brands or products:

- Form 66

Properties and advantages

- Long lifetime

- Constant jet quality

- Needle jet with high energy density

- Easy to install and disassemble

- Swiss Quality

Applications

- Automobile and aircraft industry

- Construction industry

- Mining

- Iron, steel and metal industries

- Glass, porcelain and ceramic industries.

- Lumber industry

- Municipal operations

- Agriculture

- safety- and bulletproof glass

- Shipbuilding

| ART. NO. (1) |

|---|

| 31189._ _ |

Specifications

- Operating pressure (bar) max. 3000

- Operating temp. (°C) max. 150

Downloads

Instructions

When manually operating high pressure guns and lances the repulsive force on the axis should not exceed 250N! If the repulsive force exceeds 150N, a support / body armour is required!

| < 150 N | |

| < 250 N | |

| > 250 N |