Sapphire nozzle 165

- MVT AG - micro technologies

- Products

- Surface treatment

- Sapphire screw-in nozzles

- Sapphire nozzle 165

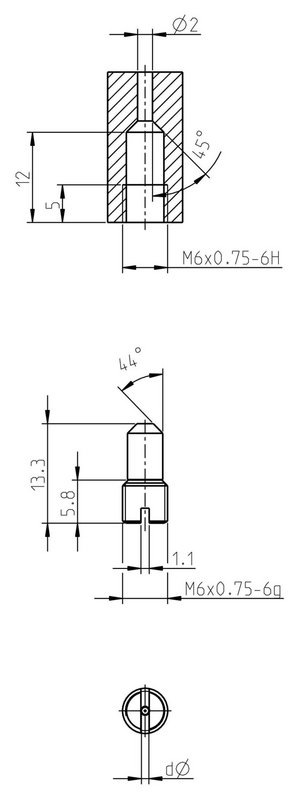

The sapphire nozzle type 165 can be used with the optional steel Inox seal up to an operating pressure of 2500 bar. With the brass seal, an operating pressure of 1000 bar is permitted. This nozzle is used in industrial cleaning or general surface treatment. The sapphire and the nozzle body are manufactured and processed in-house. The nozzle has a cone seal and has a sealing angle of 44°.

The heart of the nozzle, its the sapphire that is completely manufactured by mvt AG, thus ensuring a consistent and high quality. All sapphire are checked for scratches, cracks and flow.

This product is compatible with the following brands or products:

- Type O

Properties and advantages

- Long lifetime

- Constant jet quality

- High-power and focused water jet

- Needle jet with high energy density

- Easy to install and disassemble

- Swiss Quality

Applications

- Automobile and aircraft industry

- Construction industry

- Mining

- Chemical industry

- Iron, steel and metal industries

- Energy industry

- Beverage industry

- Glass, porcelain and ceramic industries.

- Lumber industry

- Municipal operations

- Agriculture

- Mechanical and apparatus engineering

- Offshore deployment

- Shipbuilding

| ART. NO. (1) |

|---|

| 31185._ _ |

Specifications

- Operating pressure (bar) max. 2500

- Operating temp. (°C) max. 150

Downloads

Gasket Sold Separately | ||

| Art. No. | Material | Max. pressure (bar) |

|---|---|---|

| 10025 | Steel Inox | 2500 |

| 10024 | Brass | 1500 |

Instructions

When manually operating high pressure guns and lances the repulsive force on the axis should not exceed 250N! If the repulsive force exceeds 150N, a support / body armour is required!

| < 150 N | |

| < 250 N | |

| > 250 N |