Sapphire nozzle 965

- MVT AG - micro technologies

- Products

- Surface treatment

- Sapphire screw-in nozzles

- Sapphire nozzle 965

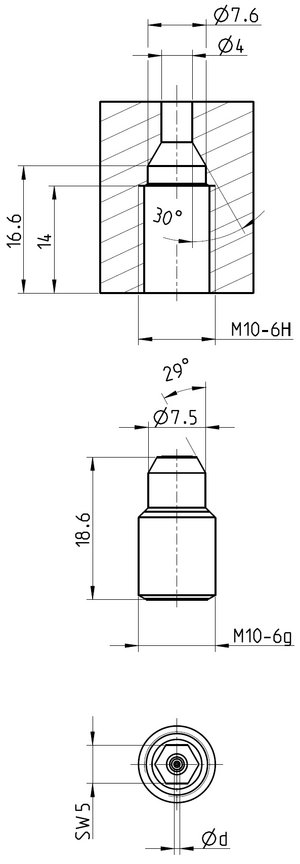

The high performance sapphire nozzle type 965 is still the most popular nozzle for surface treatment. This model was designed as a pointed nozzle for hand lance operation, or as an insert for a rotary nozzle for paint stripping on ships, and also as an insert for spray-bars. The nozzle is characterized above all by its service life, efficiency and quality and can be used up to an operating pressure of 3000 bar. The nozzle body consists of a one-piece construction with rolled thread and formed/forged hexagon socket. This manufacturing process gives our nozzle bodies higher strength reserves compared to one-piece/clamping parts.

The nozzle neck is manufactured very precisely and has a perfect concentricity with the sealing edge. The 29° sealing edge has no roundings or double angles and a greater wall thickness than conventional nozzles. Therefore there can be no deformation of the nozzle body at the sealing edge.

The heart of the nozzle, is the sapphire that is completely manufactured by mvt AG, thus ensuring uniform and high quality. All nozzle stones are checked for scratches, cracks and flow.

This nozzle has been subjected to a burst and pressure test by an accredited testing laboratory STS 0052 according to harmonized standard EN 12162+A1:2009. And withstood the 30 minute load of 3930 bar.

This nozzle is also available in ceramic and it is compatible with the following brands or products:

- Type P

- Form 21

- Series 3261

Properties and advantages

- Long lifetime

- Constant jet quality

- High-power and focused water jet

- Needle jet with high energy density

- Easy to install and disassemble

- Swiss Quality

Applications

- Automobile and aircraft industry

- Construction industry

- Mining

- Iron, steel and metal industries

- Mechanical and apparatus engineering

- Food industry

- Offshore deployment

- Shipbuilding

- Cement and concrete industry

- Concrete demolition

- Surface treatment

- Paint removal

- Spray bars

| ART. NO. (1) |

|---|

| 32176._ _ |

Specifications

- Operating pressure (bar) max. 3000

- Operating temp. (°C) max. 150

- Tightening torque (Nm) max. 25

Downloads

Instructions

When manually operating high pressure guns and lances the repulsive force on the axis should not exceed 250N! If the repulsive force exceeds 150N, a support / body armour is required!

| < 150 N | |

| < 250 N | |

| > 250 N |