Products

- MVT AG - micro technologies

- Products

Some of our products were subjected to a pressure burst test by an accredited testing laboratory STS 0052. The harmonized standard EN 12162 + A1:2009 served as the basis for the tests. Thanks to our own development of high-precision drilling machines and our own diamond tools, we are able to drill holes in sapphires, rubies, ceramics and hard metal materials.

The holes can be drilled even more precisely in the diameter range from 80µ to 3 mm using a grandissage method. The nozzle insert can also be provided with a cone using tools manufactured in-house.

The lapping of the surfaces and the processing of the edges is carried out after decades of experience. All these special machining processes lead to the results required by the customer.

The nozzle inserts are then mounted in the nozzle body without tension. This type of assembly ensures that the insert cannot be pushed out under high water pressure and that no tension is created on the insert due to a special bonding process. That`s why our insert cannot break during use. This procedure distinguishes us from other conventional mounting methods of other manufacturers.

Water jet cutting

The inlet water is typically pressurized to approx. 4000 bar (58000 PSI) by a special high-pressure…

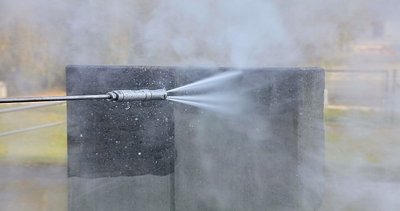

Read MoreSurface treatment

The inlet water is typically pressurized up to 3000 bar (43512 PSI) by a special high-pressure pump.…

Read MoreMONRO-JET ®

With support of the development department of Kärcher GmbH in Winnenden, mvt has developed the…

Read MorePaper industry

Our paper nozzles offer high durability, efficiency and quality and are ideal for cleaning paper…

Read MoreCustomized nozzles

With our extensive expertise and longstanding experience, we are committed to offering customized…

Read More