Ceramic nozzle 972-cer

- MVT AG - micro technologies

- Products

- Surface treatment

- Ceramic nozzles

- Ceramic nozzle 972-cer

The high-performance ceramic nozzle type 972-cer was designed for multiple tools such as spray bars or nozzle bars, but can also be used as a nozzle insert in rotary nozzles or for hand lances. The mvt ceramic nozzles have a nozzle factor of 0.95. A big advantage is that the ceramic insert cannot burst and the durability is also quite impressive and are far superior to sapphire. According to our experience, a service life of up to 150 hours can be achieved with a constant operating pressure of 2500 bar, as long as all components such as filters, connections and water are 100% OK.

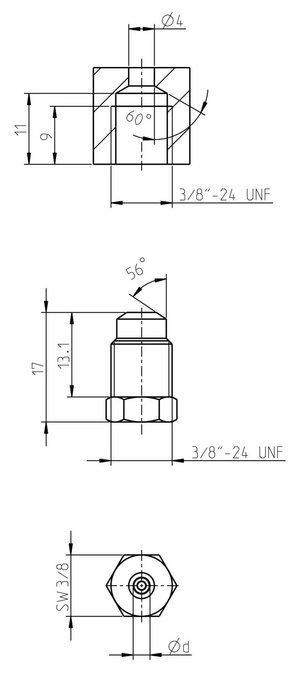

The nozzle neck is manufactured very precisely and has a perfect concentricity with the sealing edge. The 56° sealing edge has no roundings or double angles and a greater wall thickness compared to conventional nozzles. Therefore, there can be no deformation of the nozzle body at the sealing edge.

The heart of the nozzle, the ceramic insert, is completely manufactured by mvt AG, which guarantees a uniform and high quality. All ceramic inserts are checked for scratches, cracks and flow.

This product is compatible with the following brands or products:

- Series 3546/3024

- OS6™

- UHP-X

Properties and advantages

- Long lifetime

- Constant jet quality

- High-power and focused water jet

- Needle jet with high energy density

- Special coating

- Swiss Quality

Applications

- Automobile and aircraft industry

- Construction industry

- Concrete demolition

- Mechanical and apparatus engineering

- Surface treatment

- Offshore deployment

- Cement and concrete industry

- Surface cleaning

- Industrial cleaning

- Spray bars

| ART. NO. (1) |

|---|

| 31250._ _ |

Specifications

- Operating pressure (bar) max. 3000

- Operating temp. (°C) max. 150

- Tightening torque (Nm) max. 40

Downloads

| ART. NO. | NOZZLE SIZE in US Gal/min at 40 psi | NOZZLE Ød mm | PRESSURE in psi / bar | ||||||

|---|---|---|---|---|---|---|---|---|---|

| psi 14500 | psi 21750 | psi 25375 | psi 29000 | psi 31900 | psi 36250 | psi 43500 | |||

| bar 1000 | bar 1500 | bar 1750 | bar 2000 | bar 2200 | bar 2500 | bar 3000 | |||

| FLOW RATE in l/min | |||||||||

| 31250.0150 | 0006 | 0.15 | 0.442 | 0.537 | 0.578 | 0.616 | 0.644 | 0.684 | 0.744 |

| 31250.0200 | 0011 | 0.20 | 0.786 | 0.955 | 1.028 | 1.095 | 1.145 | 1.215 | 1.322 |

| 31250.0250 | 0017 | 0.25 | 1.228 | 1.492 | 1.606 | 1.710 | 1.789 | 1.899 | 2.066 |

| 31250.0300 | 0024 | 0.30 | 1.769 | 2.149 | 2.312 | 2.463 | 2.576 | 2.734 | 2.975 |

| 31250.0350 | 0033 | 0.35 | 2.407 | 2.925 | 3.147 | 3.352 | 3.506 | 3.722 | 4.050 |

| 31250.0400 | 0043 | 0.40 | 3.144 | 3.820 | 4.111 | 4.379 | 4.579 | 4.861 | 5.289 |

| 31250.0450 | 0055 | 0.45 | 3.979 | 4.835 | 5.203 | 5.542 | 5.795 | 6.152 | 6.694 |

| 31250.0500 | 0067 | 0.50 | 4.913 | 5.969 | 6.423 | 6.841 | 7.155 | 7.595 | 8.264 |

| 31250.0550 | 0082 | 0.55 | 5.944 | 7.223 | 7.772 | 8.278 | 8.657 | 9.190 | 10.000 |

Instructions

When manually operating high pressure guns and lances the repulsive force on the axis should not exceed 250N! If the repulsive force exceeds 150N, a support / body armour is required!

| < 150 N | |

| < 250 N | |

| > 250 N |