Monro-Jet F6

- MVT AG - micro technologies

- Products

- MONRO-JET ®

- Monro-Jet F6

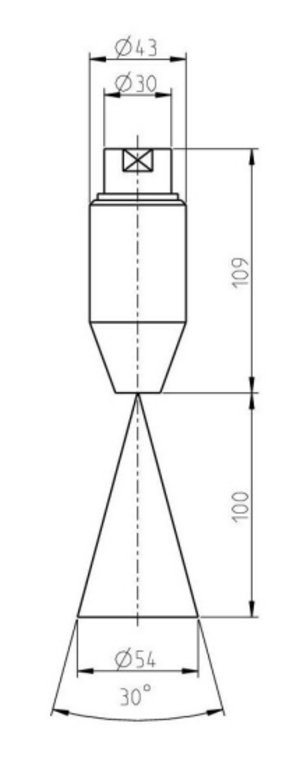

Orbital nozzle Monro-Jet F6

MONRO-JET® nozzles combine the high power of the point jet with the large area output of the flat jet. They can be used with all approved high-pressure fittings and mounted on lances. The model F6 can be used up to an operating pressure of 500 bar, and five different connection thread types are available. Due to their compact design, MONRO-JET® nozzles can be used both in building construction and in civil engineering for surface treatment and cleaning.

Properties and advantages

- Higher cleaning capacity levels

- Constant jet quality

- Long lifetime

- Light, durable and reliable

- Easy to install and disassemble

- Swiss Quality

Applications

- Surface cleaning

- Cleaning and removing flash from castings

- Offshore deployment

- Shipbuilding

- Removal of bitumen layers

- Paint removal

| Connection Thread | ART. NO. (1) |

|---|---|

| 1/4" BSP | 31457._ _ |

| 1/2" BSP | 31455._ _ |

| 1/2" NPT | 31456._ _ |

| 3/8" BSP | 31453._ _ |

| 3/8" NPT | 31454._ _ |

Specifications

- Operating pressure (bar) max. 500

- Operating temp. (°C) max. 100

- Rotor Ø (mm) from 0.60 to 1.65

Downloads

| ART. NO. | Rotor Ø | DRIVING TUBE Ø | NUMBER OF BORES | PRESSURE in psi / bar | |

|---|---|---|---|---|---|

| psi 2900 | psi 7250 | ||||

| bar 200 | bar 500 | ||||

| FLOW RATE in l/min | |||||

| 31457.0600 | 0.60 | 0.60 | 2 | 2.836 | 4.508 |

| 31457.0650 | 0.65 | 0.65 | 2 | 3.328 | 5.235 |

| 31457.0700 | 0.70 | 0.70 | 2 | 3.400 | 5.348 |

| 31457.0750 | 0.75 | 0.70 | 2 | 3.719 | 6.156 |

| 31457.0800 | 0.80 | 0.70 | 2 | 4.711 | 7.354 |

| 31457.0850 | 0.85 | 0.70 | 2 | 5.081 | 7.907 |

| 31457.0900 | 0.90 | 0.70 | 2 | 6.327 | 9.880 |

| 31457.0950 | 0.95 | 1.00 | 2 | 6.788 | 10.676 |

| 31457.1000 | 1.00 | 1.00 | 2 | 7.971 | 12.537 |

| 31457.1050 | 1.05 | 1.20 | 2 | 8.612 | 13.546 |

| 31457.1100 | 1.10 | 1.40 | 2 | 9.758 | 15.349 |

| 31457.1150 | 1.15 | 1.40 | 2 | 10.418 | 16.385 |

| 31457.1200 | 1.20 | 1.80 | 2 | 12.018 | 18.903 |

| 31457.1250 | 1.25 | 1.80 | 2 | 13.099 | 20.604 |

| 31457.1300 | 1.30 | 2.40 | 2 | 14.041 | 23.082 |

| 31457.1350 | 1.35 | 2.40 | 2 | 15.689 | 24.677 |

| 31457.1400 | 1.40 | 2.40 | 2 | 16.910 | 26.597 |

| 31457.1450 | 1.45 | 2.60 | 2 | 18.139 | 28.530 |

| 31457.1500 | 1.50 | 2.60 | 2 | 19.412 | 30.532 |

| 31457.1550 | 1.55 | 2.80 | 2 | 20.840 | 32.779 |

| 31457.1600 | 1.60 | 2.80 | 2 | 22.206 | 34.927 |

| 31457.1650 | 1.65 | 3.00 | 2 | 23.616 | 37.144 |

| 31455.0600 | 0.60 | 0.60 | 2 | 2.836 | 4.508 |

| 31455.0650 | 0.65 | 0.65 | 2 | 3.328 | 5.235 |

| 31455.0700 | 0.70 | 0.70 | 2 | 3.400 | 5.348 |

| 31455.0750 | 0.75 | 0.70 | 2 | 3.719 | 6.156 |

| 31455.0800 | 0.80 | 0.70 | 2 | 4.711 | 7.354 |

| 31455.0850 | 0.85 | 0.70 | 2 | 5.081 | 7.907 |

| 31455.0900 | 0.90 | 0.70 | 2 | 6.327 | 9.880 |

| 31455.0950 | 0.95 | 1.00 | 2 | 6.788 | 10.676 |

| 31455.1000 | 1.00 | 1.00 | 2 | 7.971 | 12.537 |

| 31455.1050 | 1.05 | 1.20 | 2 | 8.612 | 13.546 |

| 31455.1100 | 1.10 | 1.40 | 2 | 9.758 | 15.349 |

| 31455.1150 | 1.15 | 1.40 | 2 | 10.418 | 16.385 |

| 31455.1200 | 1.20 | 1.80 | 2 | 12.018 | 18.903 |

| 31455.1250 | 1.25 | 1.80 | 2 | 13.099 | 20.604 |

| 31455.1300 | 1.30 | 2.40 | 2 | 14.041 | 23.082 |

| 31455.1350 | 1.35 | 2.40 | 2 | 15.689 | 24.677 |

| 31455.1400 | 1.40 | 2.40 | 2 | 16.910 | 26.597 |

| 31455.1450 | 1.45 | 2.60 | 2 | 18.139 | 28.530 |

| 31455.1500 | 1.50 | 2.60 | 2 | 19.412 | 30.532 |

| 31455.1550 | 1.55 | 2.80 | 2 | 20.840 | 32.779 |

| 31455.1600 | 1.60 | 2.80 | 2 | 22.206 | 34.927 |

| 31455.1650 | 1.65 | 3.00 | 2 | 23.616 | 37.144 |

| 31456.0600 | 0.60 | 0.60 | 2 | 2.836 | 4.508 |

| 31456.0650 | 0.65 | 0.65 | 2 | 3.328 | 5.235 |

| 31456.0700 | 0.70 | 0.70 | 2 | 3.400 | 5.348 |

| 31456.0750 | 0.75 | 0.70 | 2 | 3.719 | 6.156 |

| 31456.0800 | 0.80 | 0.70 | 2 | 4.711 | 7.354 |

| 31456.0850 | 0.85 | 0.70 | 2 | 5.081 | 7.907 |

| 31456.0900 | 0.90 | 0.70 | 2 | 6.327 | 9.880 |

| 31456.0950 | 0.95 | 1.00 | 2 | 6.788 | 10.676 |

| 31456.1000 | 1.00 | 1.00 | 2 | 7.971 | 12.537 |

| 31456.1050 | 1.05 | 1.20 | 2 | 8.612 | 13.546 |

| 31456.1100 | 1.10 | 1.40 | 2 | 9.758 | 15.349 |

| 31456.1150 | 1.15 | 1.40 | 2 | 10.418 | 16.385 |

| 31456.1200 | 1.20 | 1.80 | 2 | 12.018 | 18.903 |

| 31456.1250 | 1.25 | 1.80 | 2 | 13.099 | 20.604 |

| 31456.1300 | 1.30 | 2.40 | 2 | 14.041 | 23.082 |

| 31456.1350 | 1.35 | 2.40 | 2 | 15.689 | 24.677 |

| 31456.1400 | 1.40 | 2.40 | 2 | 16.910 | 26.597 |

| 31456.1450 | 1.45 | 2.60 | 2 | 18.139 | 28.530 |

| 31456.1500 | 1.50 | 2.60 | 2 | 19.412 | 30.532 |

| 31456.1550 | 1.55 | 2.80 | 2 | 20.840 | 32.779 |

| 31456.1600 | 1.60 | 2.80 | 2 | 22.206 | 34.927 |

| 31456.1650 | 1.65 | 3.00 | 2 | 23.616 | 37.144 |

| 31453.0600 | 0.60 | 0.60 | 2 | 2.836 | 4.508 |

| 31453.0650 | 0.65 | 0.65 | 2 | 3.328 | 5.235 |

| 31453.0700 | 0.70 | 0.70 | 2 | 3.400 | 5.348 |

| 31453.0750 | 0.75 | 0.70 | 2 | 3.719 | 6.156 |

| 31453.0800 | 0.80 | 0.70 | 2 | 4.711 | 7.354 |

| 31453.0850 | 0.85 | 0.70 | 2 | 5.081 | 7.907 |

| 31453.0900 | 0.90 | 0.70 | 2 | 6.327 | 9.880 |

| 31453.0950 | 0.95 | 1.00 | 2 | 6.788 | 10.676 |

| 31453.1000 | 1.00 | 1.00 | 2 | 7.971 | 12.537 |

| 31453.1050 | 1.05 | 1.20 | 2 | 8.612 | 13.546 |

| 31453.1100 | 1.10 | 1.40 | 2 | 9.758 | 15.349 |

| 31453.1150 | 1.15 | 1.40 | 2 | 10.418 | 16.385 |

| 31453.1200 | 1.20 | 1.80 | 2 | 12.018 | 18.903 |

| 31453.1250 | 1.25 | 1.80 | 2 | 13.099 | 20.604 |

| 31453.1300 | 1.30 | 2.40 | 2 | 14.041 | 23.082 |

| 31453.1350 | 1.35 | 2.40 | 2 | 15.689 | 24.677 |

| 31453.1400 | 1.40 | 2.40 | 2 | 16.910 | 26.597 |

| 31453.1450 | 1.45 | 2.60 | 2 | 18.139 | 28.530 |

| 31453.1500 | 1.50 | 2.60 | 2 | 19.412 | 30.532 |

| 31453.1550 | 1.55 | 2.80 | 2 | 20.840 | 32.779 |

| 31453.1600 | 1.60 | 2.80 | 2 | 22.206 | 34.927 |

| 31453.1650 | 1.65 | 3.00 | 2 | 23.616 | 37.144 |

| 31454.0600 | 0.60 | 0.60 | 2 | 2.836 | 4.508 |

| 31454.0650 | 0.65 | 0.65 | 2 | 3.328 | 5.235 |

| 31454.0700 | 0.70 | 0.70 | 2 | 3.400 | 5.348 |

| 31454.0750 | 0.75 | 0.70 | 2 | 3.719 | 6.156 |

| 31454.0800 | 0.80 | 0.70 | 2 | 4.711 | 7.354 |

| 31454.0850 | 0.85 | 0.70 | 2 | 5.081 | 7.907 |

| 31454.0900 | 0.90 | 0.70 | 2 | 6.327 | 9.880 |

| 31454.0950 | 0.95 | 1.00 | 2 | 6.788 | 10.676 |

| 31454.1000 | 1.00 | 1.00 | 2 | 7.971 | 12.537 |

| 31454.1050 | 1.05 | 1.20 | 2 | 8.612 | 13.546 |

| 31454.1100 | 1.10 | 1.40 | 2 | 9.758 | 15.349 |

| 31454.1150 | 1.15 | 1.40 | 2 | 10.418 | 16.385 |

| 31454.1200 | 1.20 | 1.80 | 2 | 12.018 | 18.903 |

| 31454.1250 | 1.25 | 1.80 | 2 | 13.099 | 20.604 |

| 31454.1300 | 1.30 | 2.40 | 2 | 14.041 | 23.082 |

| 31454.1350 | 1.35 | 2.40 | 2 | 15.689 | 24.677 |

| 31454.1400 | 1.40 | 2.40 | 2 | 16.910 | 26.597 |

| 31454.1450 | 1.45 | 2.60 | 2 | 18.139 | 28.530 |

| 31454.1500 | 1.50 | 2.60 | 2 | 19.412 | 30.532 |

| 31454.1550 | 1.55 | 2.80 | 2 | 20.840 | 32.779 |

| 31454.1600 | 1.60 | 2.80 | 2 | 22.206 | 34.927 |

| 31454.1650 | 1.65 | 3.00 | 2 | 23.616 | 37.144 |

Instructions

When manually operating high pressure guns and lances the repulsive force on the axis should not exceed 250N! If the repulsive force exceeds 150N, a support / body armour is required!

| < 150 N | |

| < 250 N | |

| > 250 N |

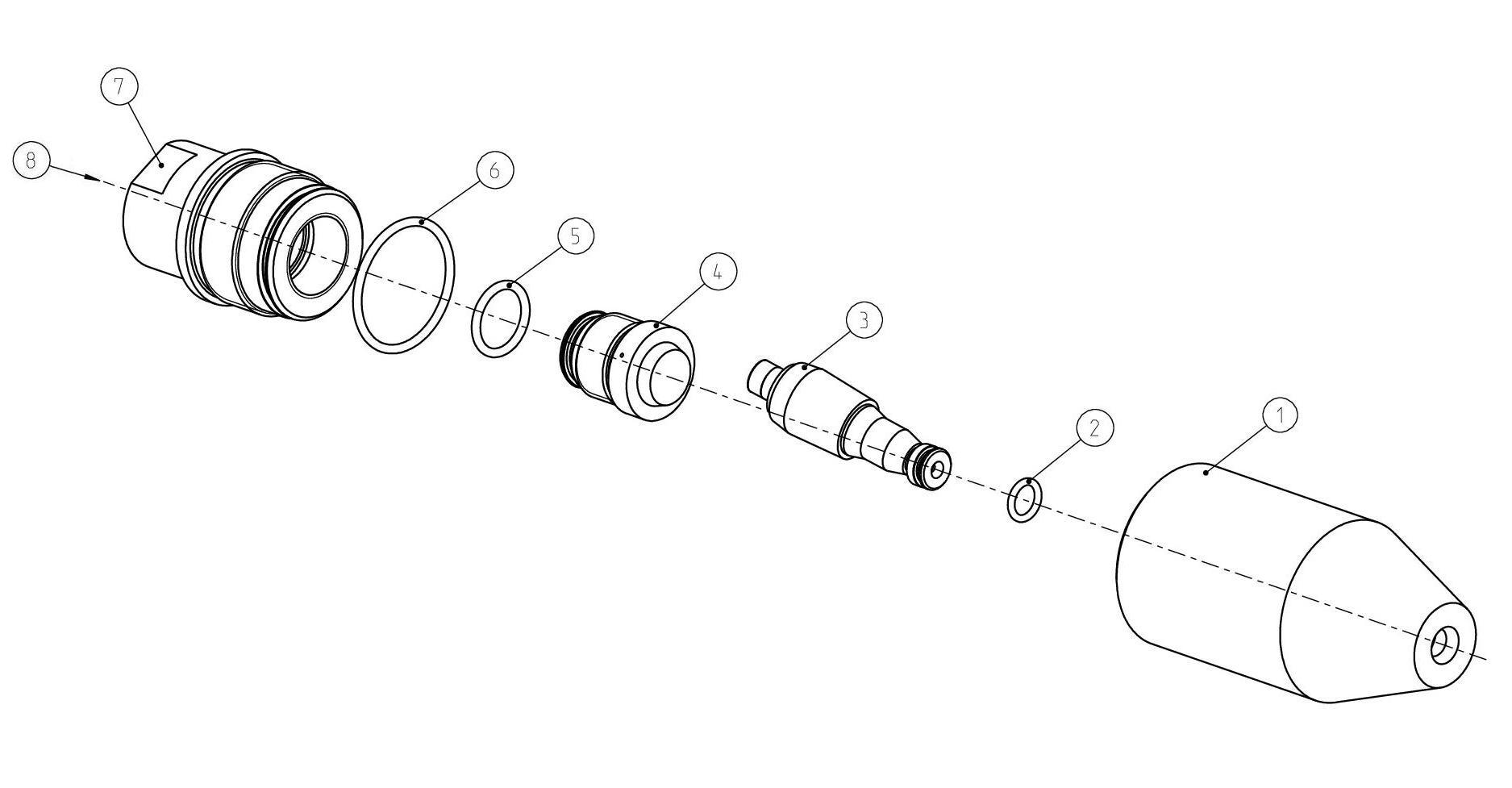

Spare Parts

1. Nozzle body F6

| Article No |

|---|

| 10345 |

2. O-Ring D7.1 X 1.6 for repair kit

| Article No |

|---|

| 10271 |

3. Rotorset type F6

| Article No | Rotor |

|---|---|

| 32233 | 0.60 |

| 32234 | 0.65 |

| 32235 | 0.70 |

| 32236 | 0.75 |

| 32237 | 0.80 |

| 32238 | 0.85 |

| 32239 | 0.90 |

| 32240 | 0.95 |

| 32241 | 1.00 |

| 32242 | 1.05 |

| 32243 | 1.10 |

| 32244 | 1.15 |

| 32245 | 1.20 |

| 32246 | 1.25 |

| 32247 | 1.30 |

| 32248 | 1.35 |

| 32249 | 1.40 |

| 32250 | 1.45 |

| 32251 | 1.50 |

| 32252 | 1.55 |

| 32253 | 1.60 |

| 32254 | 1.65 |

| 32255 | 1.70 |

| 32256 | 1.75 |

| 32257 | 1.80 |

| 32258 | 1.85 |

| 32259 | 1.90 |

| 32260 | 1.95 |

| 32261 | 2.00 |

| 32262 | 2.05 |

| 32263 | 2.10 |

| 32264 | 2.15 |

| 32265 | 2.20 |

| 32266 | 2.25 |

| 32267 | 2.30 |

| 32268 | 2.35 |

| 32269 | 2.40 |

| 32270 | 2.45 |

| 32271 | 2.50 |

| 32272 | 2.55 |

| 32273 | 2.60 |

| 32274 | 2.65 |

| 32275 | 2.70 |

| 32276 | 2.75 |

| 32277 | 2.80 |

4. Driving tube

| Article No | Driving Tube | Number Bores |

|---|---|---|

| 10402 | 0.60 | 2 |

| 10403 | 0.65 | 2 |

| 10404 | 0.70 | 2 |

| 10405 | 0.75 | 2 |

| 10406 | 0.80 | 2 |

| 10407 | 1.00 | 2 |

| 10408 | 1.20 | 2 |

| 10409 | 1.40 | 2 |

| 10410 | 1.80 | 2 |

| 10411 | 2.40 | 2 |

| 10412 | 2.60 | 2 |

| 10413 | 2.80 | 2 |

| 10414 | 3.00 | 2 |

5. O-Ring D14 x 2 for driving tube

| Article No |

|---|

| 10272 |

6. O-Ring D28 x 2 for inlet cover

| Article No |

|---|

| 10274 |

7. Inlet cover

| Article No | Connecting Thread |

|---|---|

| 11505 | 1/4“ BSP |

| 11503 | 1/2“ BSP |

| 11504 | 1/2“ NPT |

| 11502 | 3/8“ BSP |

| 11501 | 3/8“ NPT |

8. Connection thread seal

| Article No | Description | Inlet Cover |

|---|---|---|

| 10273 | O-Ring Ø15x2 | 3/8“ BSP |

Accessories

Mounting tool

| Article No |

|---|

| 10269 |